This post is also available in:

Español

Português

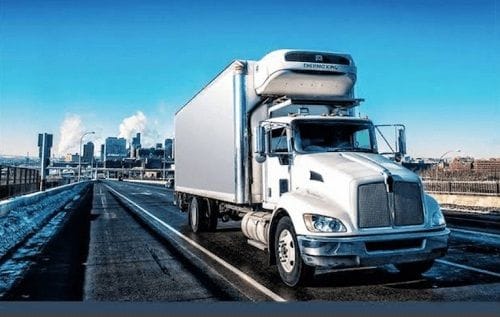

Cold Chain (cadena de frío in Spanish) essentially means that a product in distribution is kept refrigerated at a constant temperature at all times, including during transportation.

The cold chain distribution is nothing new; daily, we see refrigerated trucks and vans on streets and highways, primarily used for distributing food products, often as a serious matter of health and food safety, but also to preserve the freshness and quality of the products.

This is what makes this type of distribution a “chain,” as all links are kept at the same refrigeration temperature, from the producer to the consumer.

Contenido

Stages of a Cold Chain

If we were to simplify it, the stages of distribution in a cold chain would be as follows:

- Storage at the brewery at around 4°C (39.2°F)

- Transportation at 4°C

- Distribution warehouse at 4°C

- Transportation at 4°C

- Retailer in a cooler at 4°C

- Consumer refrigerator at 4°C

At the most basic level, the choice of a cold chain temperature of 4°C (39.2°F) is due to it being a standard in food handling, as there is a vast amount of infrastructure and equipment configured to this temperature, known as “refrigerator temperature.”

Additionally, it is the reference temperature used by most studies and associated scientific literature, such as the renowned book Freshness by English scientist Charles Bamforth.

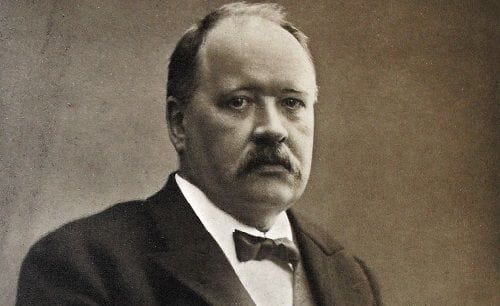

In the mentioned book, Dr. Bamforth refers to the work of Swedish scientist Svante August Arrhenius, Nobel Prize in Chemistry in 1903, who in 1889 discovered that the rate of chemical reactions increases with temperature, in a relationship proportional to the concentration of existing molecules.

In the specific case of beer, this reaction accelerates up to 3 times (3X) for every 10°C (50°F) increase in temperature.

Key Considerations About the Cold Chain

The aging of beer is a complex chemical and biochemical process with many facets, where the key factor is the exponential nature of the rate of chemical change relative to temperature.

In many cases, the conditions under which the product reaches the final stage of its commercialization process are entirely out of the brewer’s control, and this point is critical in guaranteeing flavor.

Of course, changes in beer are continuous, beyond the general consideration that “consume before the date” is a kind of quality cliff.

The question then is how the cold chain affects the flavor stability of a beer that had to be transported and stored in different stages and places compared to the same beer served at its place of origin. Is “proximity” synonymous with freshness?

In general, the freshness of beer is related to several factors:

- Level of dissolved oxygen

- Storage temperatures

- Bottling date

The term aging is used to describe the changes in aromas and flavors produced in beer during storage compared to freshly finished beer.

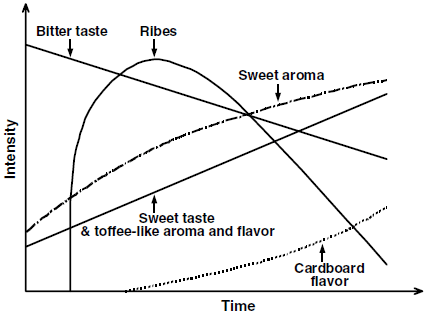

Although not all beers age the same, and aging can vary from one style to another, the following changes were described by Dalgliesh in 1977 and can be summarized in the following chart:

As we can see, one of the factors that most strongly influences beer aging is temperature, as it increases, so does the kinetic energy of the molecules that make it up, accelerating the chemical reactions that produce it.

The Arrhenius Equation

The Arrhenius equation is a mathematical expression that demonstrates the dependence of the rate constant (kinetics) of a chemical reaction on the temperature at which the reaction occurs.

The equation was originally proposed by Dutch chemist J. H. van ‘t Hoff in 1884, but it was in 1889 that Swedish chemist Svante Arrhenius established a physical justification and interpretation for the equation.

According to the Arrhenius equation, storing beer at a temperature close to 4°C (39.2°F) is the only way to slow down the reactions involved in aging, so that a freshly bottled beer stored at an ambient temperature of 20°C (68°F) will have a flavor shelf life of about 100 days, while storage at 4°C would ensure product freshness for 12 months.

The formula for the reaction rate is as follows:

[math] k = A \cdot e^{-\frac{E_a}{RT}} [/math]

Where:

- k: Rate constant

- A: Frequency of collisions between two molecules

- R: Universal gas constant (8.314 J/mol-K)

- T: Temperature in Kelvin

- Ea: Activation energy

This is a major concern when there is a large amount of beer stored or traveling somewhere, under conditions that can often exceed temperature cycles of up to 40°C (104°F).

| Temperature | Shelf Life |

| 4°C (39,2°F) | 12 months |

| 10°C (50°F) | 9 months |

| 20°C (68°F) | 3 months |

| 30°C (86°F) | 1 month |

| 40°C (104°F) | 10 days |

Stability and Recommendations

As a consequence, depending on how quickly the product moves, the likelihood of the beer spoiling increases dramatically.

The date that should matter most to us, then, should not be the production date or the recommended consumption date, but the date when the cold chain was broken.

Therefore, the only solution to extend product stability is to maintain the cold chain for as long as possible during distribution.

Cold Chain Break-Even Point

Considering that both the investment and the higher energy consumption can increase costs by up to 30% compared to “normal” distribution, it is understandable that a distributor carefully weighs the change in their cold logistics, especially if that investment will affect their profit margin.

In this equation, it is important to include both the brewery and the end consumer, both prepared to pay a little more for better service or for a product delivered with the highest quality of consumption.

This, undoubtedly, is the path to achieving excellence in product quality, but there are many obstacles, especially economic ones, that hinder its achievement.

Consumer Perspective

From the consumer’s perspective, it is necessary to clarify some points that could cause confusion.

Associating proximity with freshness should be true, but not always is invested in maintaining the cold chain, even if the sales route is very short; a product without a cold chain can deteriorate in a few days.

Associating the production date with a higher quality product, unless consumed freshly bottled, ceases to be valid if the cold chain has been broken.

As a consequence of the above, there are products with five or six months on the market that have maintained the cold chain since production, which are fresher and in better condition than products produced just a couple of weeks ago and poorly stored at high temperatures.

No se encontraron productos.

We recommend

- Why Do We Celebrate St. Patrick’s Day? Origin, History, and Traditions

- The History and Origins of Corona Extra Beer in Mexico and the World