This post is also available in:

Español

Português

World Backup Day serves as a reminder to protect crucial digital assets in beer production, from recipes and label designs to equipment configurations and laboratory software.

These elements form the operational heart of any brewery, whether craft or industrial, and their loss can have significant consequences.

Contenido

Data as a fundamental pillar

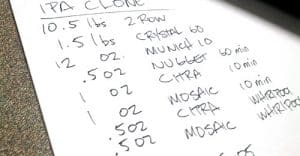

In the brewing industry, data goes beyond simple records. Recipes, with their precise ingredient formulations and fermentation times, are essential for maintaining product consistency.

Additionally, quality control systems that monitor variables like temperature, pH, and density are crucial for regulatory compliance and food safety assurance.

Another critical aspect is label design, which not only reflects brand identity but also contains mandatory legal information.

Losing these files can cause costly production and distribution delays.

Similarly, laboratory software used for chemical and microbiological analysis represents indispensable tools that require constant backup to avoid quality control process interruptions.

Common threats

Risks don’t always come from sophisticated cyberattacks. Often, everyday issues like server failures, storage device damage, or even human error can lead to valuable data loss.

A malfunctioning fermentation control system may lose customized configurations that took months to perfect.

Mobile devices or laptops used for inventory management or production data recording can be stolen or damaged.

Even poorly executed updates can corrupt critical software used in laboratories or production management systems.

Recent studies on digital security in the food industry show that over 60% of companies affected by data loss experienced significant operational disruptions.

However, those that implemented regular backup protocols recovered quickly, minimizing impacts on production and distribution.

Practical recommendations

To ensure protection of key data in the brewing industry, it’s important to adopt specific practices.

Saving copies of all formulas and production procedures in a secure system, whether physical or cloud-based, is fundamental.

Organizing files clearly, separating recipes, processes, and quality control data will facilitate emergency recovery.

Label designs also deserve special attention. It’s necessary to back up all graphic files, ensuring they’re updated and accessible when needed.

Periodically verifying these files aren’t corrupted is a simple but crucial task to prevent future problems.

Custom configurations for equipment like fermentation tanks, filtration systems, and bottling lines should be documented and regularly backed up.

When using proprietary software to control this equipment, keeping installation copies and licenses in a secure location is recommended.

Additionally, data generated by laboratory software, including chemical analysis reports and microbiological studies, should be stored in an automatic backup system to ensure availability for future audits or consultations.

Establishing a clear backup schedule, ideally aligned with production cycles or important deliveries, helps maintain updated information.

Protecting storage systems with robust passwords and multifactor authentication, especially for cloud solutions, adds an extra security layer.

The importance of planning

Implementing a backup system not only protects against unexpected losses but also provides greater operational flexibility.

For example, when a brewery expands to new locations, having updated copies of recipes, equipment configurations, and other key data will facilitate process replication and consistent standard maintenance.

Moreover, in the competitive craft beer market where innovation is key, preserving accumulated knowledge and R&D data ensures companies can continue evolving without losing achieved progress.

Final thoughts

World Backup Day presents an opportunity to reflect on the importance of protecting data that supports daily operations and growth in the brewing industry.

From recipes and designs to equipment configurations and laboratory software, each element plays a crucial role in business success.

Implementing solid backup practices not only prevents costly losses but also contributes to efficiency, consistency, and innovation capacity in this dynamic sector.

Recommended reading

- 5 sugar adjuncts you could incorporate into your beer production

- “The Beer Hunter”: Michael Jackson and Discovery Channel series with Spanish subtitles