This post is also available in:

Español

Português

The rise of non-alcoholic or low-alcohol beers (<0.5% ABV) has driven the brewing industry to explore new yeast strains and fermentation techniques.

These innovations allow for the reduction of alcohol content without sacrificing flavor, a challenge that has spurred the development of specialized yeasts.

Contenido

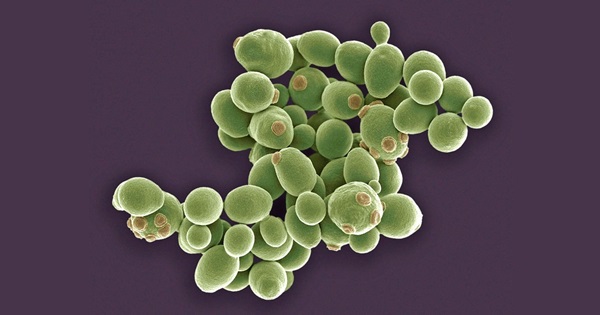

Yeasts for non-alcoholic beers

Unlike traditional beers, where complete sugar fermentation is key, the goal in non-alcoholic beers is to limit or prevent ethanol production without compromising flavor profiles.

1. Modified Saccharomyces Strains

Traditional strains of Saccharomyces cerevisiae, the most commonly used yeast in brewing, have been genetically modified or selectively bred to limit their ethanol-producing capabilities.

These modified yeasts metabolize sugars less efficiently, resulting in lower alcohol generation. Some strains have altered metabolic pathways that block the conversion of sugars into ethanol.

While others simply have a reduced ability to ferment complex sugars, leaving more residual sugar in the wort.

Examples of modified strains include Saccharomyces cerevisiae var. Ludwigii, used in some non-alcoholic beers for its low attenuation, and lab-developed strains that specifically block ethanol production.

2. Non-Conventional Yeasts

Strains like Torulaspora delbrueckii and Lachancea thermotolerans are gaining popularity for their ability to produce complex flavors with minimal alcohol production.

These non-conventional yeasts offer an alternative to traditional Saccharomyces, delivering unique aromatic profiles and more controlled fermentation.

Torulaspora delbrueckii is known for producing fruity and spicy flavors, similar to those in high-fermentation beers, but with significantly lower alcohol output. It is ideal for styles like non-alcoholic witbiers and saisons.

Lachancea thermotolerans stands out for its ability to produce lactic acid during fermentation, adding a refreshing acidity. It is perfect for non-alcoholic sour beers like Berliner Weisse or Gose.

3. Non-Fermentative Yeasts

Some yeasts, such as certain species of Pichia or Candida, are used to impart flavor without fermenting sugars.

These yeasts do not convert sugars into alcohol but produce aromatic compounds that contribute to the beer’s flavor and aroma.

They are primarily used in combination with other techniques, such as interrupted fermentation or enzyme use, to create non-alcoholic beers with complex flavor profiles.

Commercial Yeast Strains

The development of specialized yeast strains has been crucial for producing non-alcoholic or low-alcohol beers.

These strains, designed to limit ethanol production while maintaining appealing flavor profiles, are revolutionizing the industry.

1. Fermentis SafBrew™ LA-01

Produced by Fermentis, the Saccharomyces cerevisiae var. chevalieri strain is widely used in non-alcoholic beer production.

This variety does not metabolize maltose or maltotriose, two key complex sugars in traditional fermentation, but it does metabolize basic sugars like glucose, fructose, and sucrose, allowing for controlled and limited fermentation.

It is ideal for light styles such as non-alcoholic blond lagers and blonde ales, as its controlled fermentation helps brewers maintain a perfect balance between flavor and reduced alcohol content.

2. LALBREW® NOLA™

Developed by Lallemand, this modified Saccharomyces cerevisiae strain, created through hybridization, cannot ferment maltose or maltotriose, resulting in very low attenuation.

It also produces high levels of fruity esters, such as isoamyl acetate, which compensate for the lack of alcoholic complexity and add fruity and aromatic notes.

Its fermentation is quick and occurs at moderate temperatures (15–20°C), making it ideal for styles like Session IPA or Pale Ale with less than 0.5% ABV.

3. LEVULIA® AROM

Produced by Lesaffre, the non-conventional yeast Torulaspora delbrueckii is known for its ability to metabolize sugars without generating high ethanol levels.

Its main advantage is its ability to enhance fruity notes, helping to reduce the perception of “lack of body” in non-alcoholic beers.

This strain also has high tolerance to stress conditions, such as low pH and high pressure, making it versatile for various fermentation processes, often in combination with Saccharomyces strains.

4. VINIFERM® LT

Produced by DSM-Food Specialties, the Lachancea thermotolerans strain is highly valued for its ability to produce organic acids, such as lactic acid, which balance residual sweetness in non-alcoholic beers.

This yeast reduces alcohol production by 30–40% compared to traditional strains, making it ideal for beers with less than 1% ABV.

Its optimal fermentation occurs at temperatures of 25-30°C and is especially recommended for sour beers or non-alcoholic sours, as it eliminates the need for artificial acidification.

5. White Labs WLP675

Produced by White Labs, the Saccharomyces ludwigii strain is a natural yeast with low ability to metabolize complex sugars like maltose and maltotriose.

This results in a slow and stable fermentation, ideal for high controlled attenuation processes, generating fruity profiles, with notes of banana and clove, typical in wheat beers, but with an alcohol content of less than 1% ABV, especially recommended for styles such as Hefeweizen or Witbier.

6. Munich Classic – LALLEMAND

Produced by Lallemand, the Saccharomyces bayanus (Munich Classic) strain is traditionally used in winemaking but has been adapted for beer production.

Although it has a high tolerance to ethanol, its ability to selectively ferment simple sugars makes it ideal for beers with low alcohol content, generating nutty and caramel notes, perfect for styles such as Dark Lager or non-alcoholic Stout.

7. CRISPR-Modified Yeast

Using gene-editing techniques like CRISPR, these yeasts have been modified to block key enzymes in ethanol synthesis, such as alcohol dehydrogenase.

This allows for a 90% reduction in alcohol production without affecting the generation of aromatic compounds. Although still in the experimental phase, their commercial potential is immense.

However, they face significant regulatory challenges, especially in the EU, where regulations on genetically modified organisms (GMOs) are strict.

Techniques for Reducing Alcohol

Producing non-alcoholic or low-alcohol beers depends not only on the yeast strains used but also on the fermentation techniques employed.

1. Interrupted Fermentation

This method involves stopping fermentation before significant alcohol production occurs, either by controlling temperature or removing the yeast.

For example, rapidly cooling the wort halts yeast activity, limiting ethanol production.

2. Limited Attenuation

Selecting yeasts with low sugar conversion efficiency is another strategy, reducing the final alcohol content.

An example is the Saccharomyces cerevisiae var. Ludwigii strain, used in non-alcoholic beers due to its low attenuation.

3. Secondary Fermentation

Some breweries use a secondary fermentation with specialized yeasts to remove alcohol precursors or adjust flavor profiles.

For instance, Brettanomyces yeast can be used in small amounts to add aromatic complexity without increasing alcohol content.

Commercial Examples

The growing demand for non-alcoholic beers has led many breweries to innovate in their brewing processes, combining specialized yeast strains with advanced fermentation techniques.

Heineken 0.0

Heineken uses a combination of specialized yeasts and controlled fermentation techniques. Fermentation occurs at low temperatures and is interrupted before significant alcohol is generated.

The beer then undergoes vacuum distillation to remove alcohol, preserving its characteristic flavors.

BrewDog Nanny State

BrewDog employs a mix of light malts and low-fermentation yeasts. Fermentation is conducted at controlled temperatures to limit alcohol production.

A secondary fermentation with specific yeasts is used to adjust the flavor profile and ensure a balanced final product.

Erdinger Alkoholfrei

This German beer uses a special yeast that ferments at low temperatures, limiting alcohol production.

After primary fermentation, the beer undergoes a filtration process to remove any traces of alcohol, maintaining a rich and refreshing flavor.

References

- Bamforth, C. W. Brewing materials and processes: A practical approach to beer excellence. Academic Press.

- Stewart, G. G., & Russell, I. Brewing and distilling yeasts. Springer.

- Gibson, B., Geertman, J. M. A., Hittinger, C. T., Krogerus, K., Libkind, D., & Louis, E. J. New yeasts—new brews: Modern approaches to brewing yeast design and development. FEMS Yeast Research, 17 (4), fox038. https://doi.org/10.1093/femsyr/fox038

We recommend

- The Steel and Aluminum Tariffs That Could Crush Many U.S. Breweries

- Canada Blocks Import and Sale of U.S.-Produced Beers