This post is also available in:

Español

Português

Water is the most abundant ingredient in beer and a crucial element in developing the final flavor characteristics.

Historically, brewers worldwide have used locally available water to make their beer, leading to the development of beer styles associated with specific water profiles from particular regions.

For example, water in Dortmund, Western Germany, is very hard and rich in calcium, sulfates, and chlorides. Meanwhile, the Czech city of Plzen has very soft water, low in sulfates and bicarbonates.

Over time, brewers learned that to reproduce these profiles consistently, they needed to treat their water’s quality and composition as a fundamental starting point.

Contenido

How Does Water Affect Beer Flavor?

Since beer contains approximately 90-95% water, its quality and composition naturally have a significant impact on the final flavor.

Three main elements affect beer flavor: mineral composition, pH, and alkalinity.

Water hardness and mineral composition impart flavor and influence fermentation, while pH promotes enzymatic action during mashing and yeast proliferation during fermentation.

Alkalinity creates a buffer to protect pH from fluctuations during brewing, preventing bacterial growth and eliminating excess tannins.

These three factors are intrinsically linked and work together to guide the flavor and color of beer.

Home Water Filtration Systems

Today, reverse osmosis has become the brewing industry’s preferred water filtration system.

There are also systems using catalytic carbon that help remove chloramines from water, improving its taste.

Finally, water distillation and deionization also produce exceptionally pure water.

1. Reverse Osmosis

Reverse osmosis produces soft, slightly acidic water free from flavor-ruining contaminants like iron, nitrites, chlorine, and chloramines.

Using reverse osmosis-treated water gives brewers a blank slate to design and execute recipes under ideal conditions, allowing complete control over the water’s ionic composition.

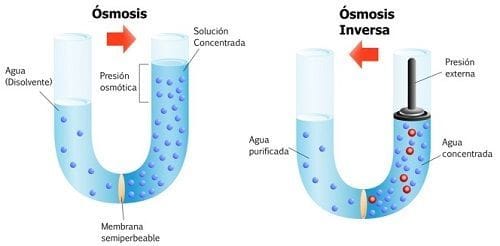

The water purity comes from forcing water slowly through a semi-permeable membrane with extremely small pores that block even microscopic contaminants while allowing water molecules through.

While osmosis equalizes solution concentrations across a membrane, reverse osmosis does the opposite – separating pure water from dissolved matter. Contaminants are discarded as “brine,” while pure “permeate” water collects in a storage tank.

No se encontraron productos.

2. Carbon Filters

If not ready to invest in reverse osmosis, an activated carbon filtration system will provide water without chlorine’s unpleasant aftertaste.

In fact, reverse osmosis systems use carbon pre-filters and post-filters to protect the membrane from chlorine and improve water taste/odor.

Through absorption, activated carbon filters trap organic compounds on their extensive surface area. Their micron-sized pores reduce chlorine, sediment, and VOCs from water.

Carbon filtration is the best method for removing chloramine from drinking water, though more challenging. Slowing water flow through the filter increases chloramine reduction.

If satisfied with your water’s mineral composition for the desired beer style, carbon filtration effectively removes chlorine taste.

No se encontraron productos.

3. Water Distillers

Water distillers, like reverse osmosis, produce water devoid of minerals, metals, or organic content by mimicking Earth’s natural water purification process.

Distillers boil small amounts of water, completely evaporating them and then recondensing them. All contaminants remain in the boiling chamber.

However, distillation (taking 4-6 hours per gallon) is only practical for homebrewing small batches, not commercial-scale production.

4. Deionization

Deionization systems remove mineral content through ion exchange, using resin beds to replace cations (iron, sodium, calcium) with hydrogen ions and anions (carbonates, sulfates) with hydroxide ions.

This produces high-purity water composed only of hydrogen and oxygen, widely used in the medical, pharmaceutical, cosmetic, and electronics industries, often combined with reverse osmosis.

No se encontraron productos.

5. UV Purification

For well water sources, ultraviolet purification neutralizes pathogens by deactivating their reproductive capacity using UV light.

Even with reverse osmosis, adding UV purification is recommended for microbiologically unsafe sources. Installing a sediment filter beforehand optimizes performance, as UV struggles with turbid water.

No se encontraron productos.

Recommended

- Bill Gates acquires Heineken stake with $902 million investment

- Personalized beers and other perfect gifts for beer lovers